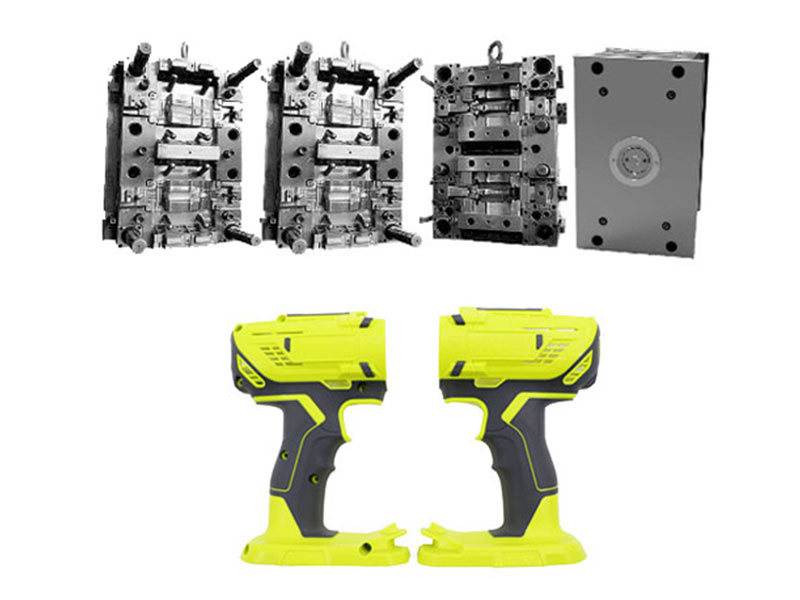

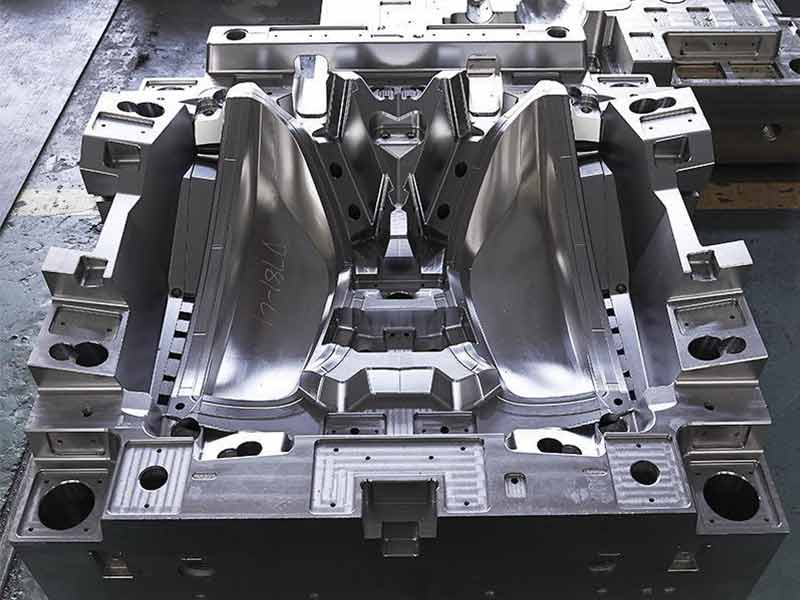

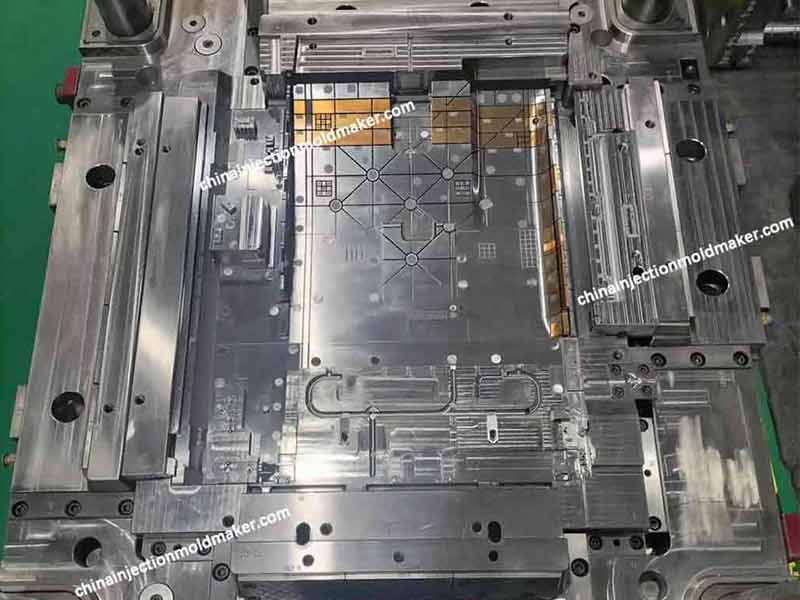

Mold design, manufacturing, injection molding, surface treatment, and assembly are complete services. Specializing in high-end mold manufacturing for medical accessories, automotive parts, OA office equipment, and home appliances. Global partners include Volkswagen, Epson, Brother, Kyocera, Canon, and Ricoh.

Plastic Mold Manufacturer

2K-mold

Silicone-mold

Your Trusted Partner for Precision Mold and Injection Molding Services!

With over 14 years of experience, we specialize in designing and manufacturing precision molds for a wide range of industries. From printers and copiers to automotive parts and household appliances, our expertise covers diverse product categories. We offer a one-stop solution, ensuring seamless integration from design to production. Our commitment to quality, timely delivery, and competitive pricing sets us apart as your ideal partner for all your mold manufacturing needs. Contact us today to discuss how we can bring your project to life!

FEATURED PRODUCTS

Specialized Services Tailored to Your Needs

With over 13 years of experience, we specialize in designing and manufacturing precision molds for a wide range of industries. Our state-of-the-art facility is equipped with advanced processing equipment, including Japanese-imported CNC machines, slow wire cutting machines, and mirror EDM machines, ensuring the highest level of precision and quality.

In addition to our cutting-edge equipment, we offer a comprehensive range of supporting services. Our team of experienced designers utilizes software such as UG, PROE, CREO, SOLIDWORKS, CATIA, and POWERMILL for mold design. We also provide in-house mold testing, trial production, and modification services, guaranteeing timely delivery and customer satisfaction.

Furthermore, we offer a variety of additional services such as assembly, painting, silk-screening, and more. From concept to completion, we provide a one-stop solution for all your mold manufacturing and injection molding needs. Contact us today to discuss how we can turn your ideas into reality!

Our Strengths

-

Quality Assurance Expertise

Our commitment to quality is unwavering. With meticulous attention to detail and a robust QC process, we ensure every mold and molded part meets the highest standards. It's not just about meeting expectations; it's about surpassing them with flying colors.

-

Swift Delivery Solutions

In the fast-paced world of manufacturing, time is of the essence. With streamlined processes and efficient production, we deliver molds and injection-molded parts at lightning speed. Your deadlines are our deadlines, and we take them seriously.

-

Tailored Solutions Just for You

We understand that every client is unique, and so are their needs. That's why we offer personalized service tailored to your specific requirements. Whether it's custom mold designs or specialized injection molding techniques, we're here to adapt and innovate.

-

Clear Communication Every Step of the Way

We pride ourselves on clear and effective communication. From initial discussions to final product delivery, you'll always be kept in the loop. We speak your language, whether it's mold jargon or plain English.