14 YEARS

-

We were established in 2011.

The company has a mold manufacturing base of over 2,000 square meters and an injection molding workshop of over 2,000 square meters.

-

We have the capacity to produce 50 sets of molds per month.

We have 8 mold designers and 35 master mold makers, with all processes completed in-house.

-

We can provide our clients with 1 million injection molding services per month.

We have 15 injection molding machines of various models, staffed with senior injection engineers and equipped with 8 QC personnel trained in Europe.

14 years specializing in plastic mold manufacturing.

Established in 2011, Shenzhen DAYSTARMOLD Co., Ltd. is a leading injection moulding manufacturer in China. DAYSTARMOLD specialises in the production of plastic moulds for automotive, medical equipment, OA office supplies, household appliances, sports products, electronic devices, e-cigarettes and printer accessories. We have passed ISO9001:2015 international quality system and TS 16949, always focusing on customer’s product quality and committed to serving the world.

We have a full set of processing equipment, the whole process is completed in the factory to ensure the quality of plastic moulds and delivery on time.

Equipments: 5 sets of CNC machining centre imported from Japan, 2 sets of Shadick slow-feeding wire imported from Japan, 7 sets of EDM, 1 set of large mould closing machine, a full set of testing equipment: three-dimensional inspection, two-dimensional inspection, hardness tester, microscope, needle gauge, micrometer, and so on. Total 15 sets of injection moulding machines of various models

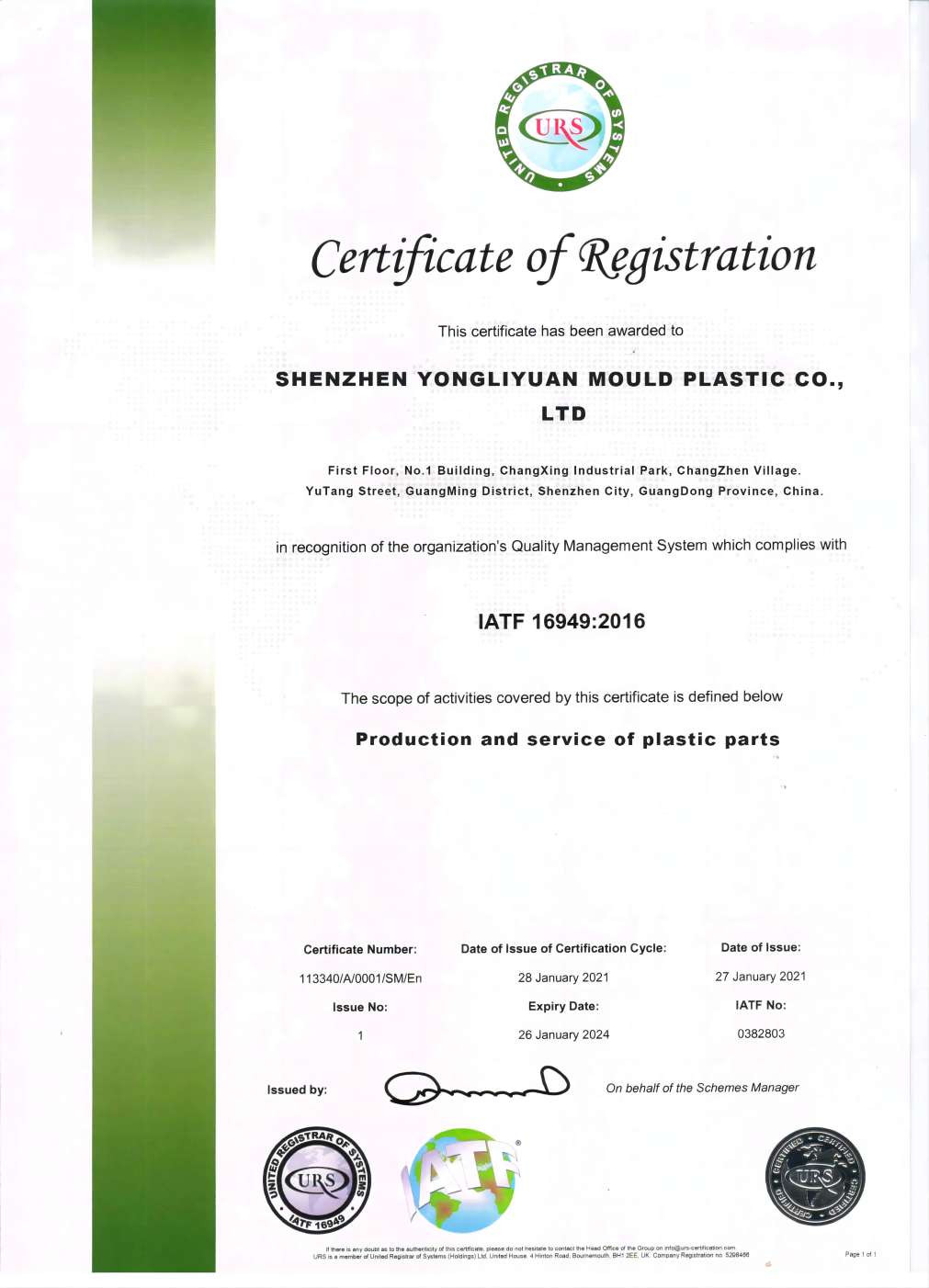

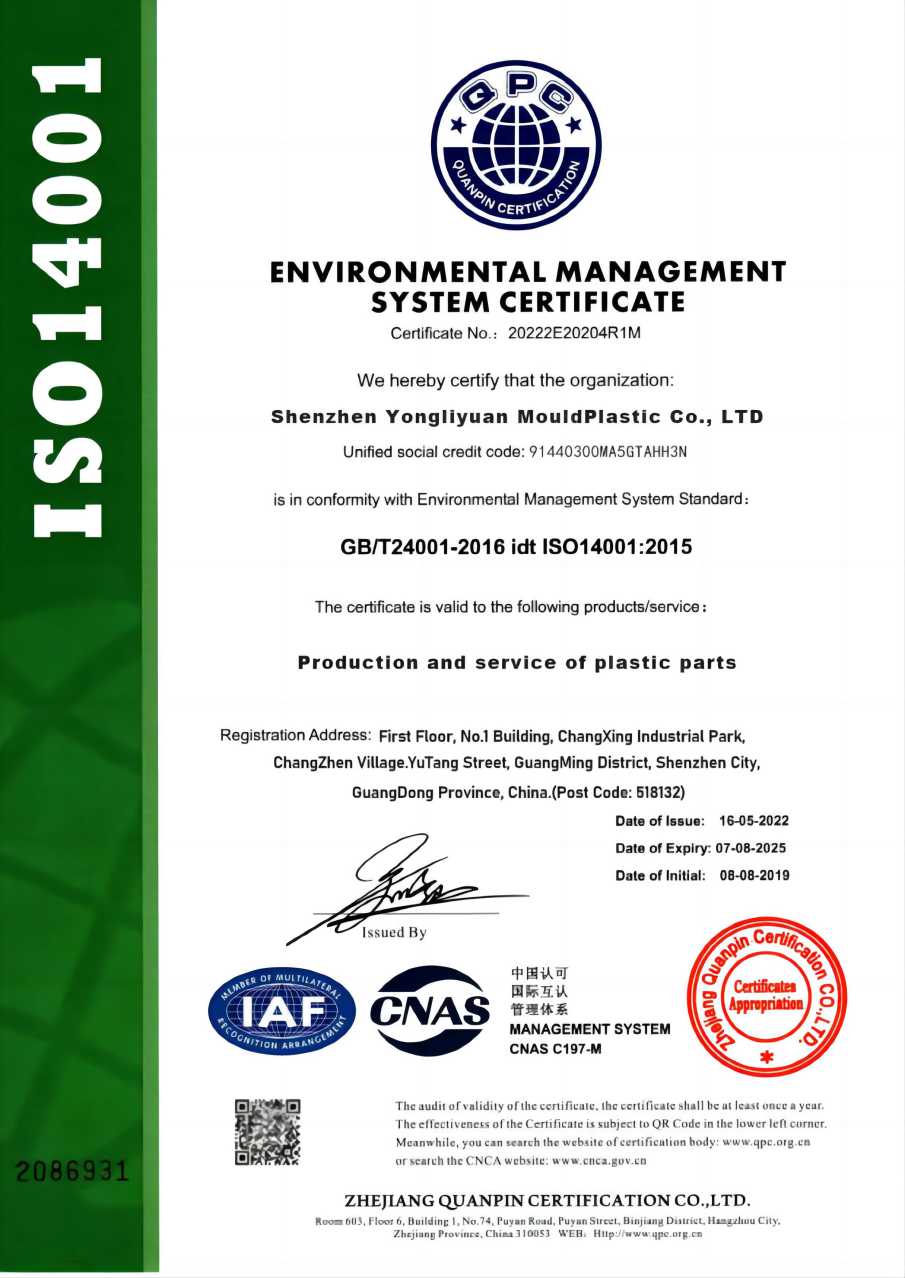

Our CERTIFICATEs

16529449705918958(1)

R(1)

16529449705918958(1)

We have a complete set of mold processing equipment, with all processes completed in-house, ensuring quality control.

Advanced Equipment: Includes 2 Japanese-imported Sodick slow wire-cut machines (ALN400Q), 7 Japanese-imported Sodick mirror spark machines, coordinate measuring machines, and other high-end processing and testing equipment.

Substantial Production Capacity: Equipped with large-scale die sinking machines (1300x1200x600H mm) and large overhead cranes (10T).

Experienced Talent: 20 toolmakers with 15 years of experience and 6 senior designers, all staff receive high-standard training and certification.

Certification and Quality Assurance: Certified with ISO 9001 international quality system, ensuring products and services meet international standards.

Focused on providing global customers with one-stop services for precision plastic mold design, manufacturing, and injection molding.