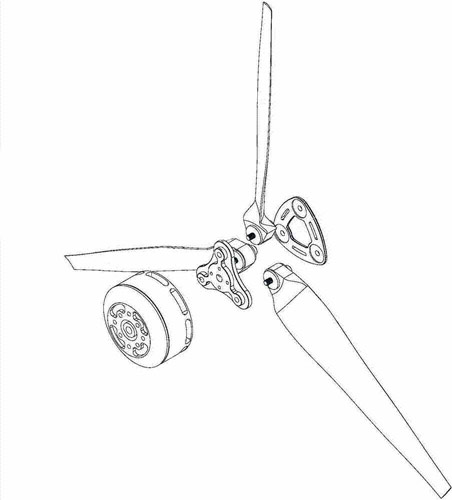

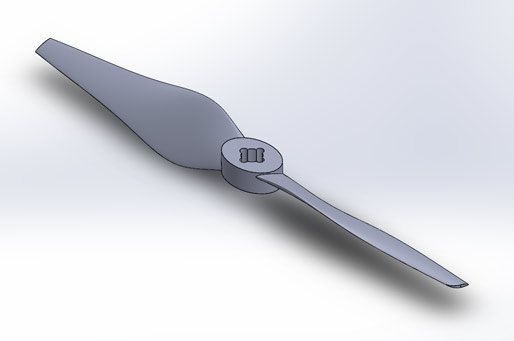

Drone Paddle Mold Manufacturing Service-Customized Solutions

With the rapid advancement of drone technology, the precision and efficiency of components such as propellers (paddles) have become critical to a drone's overall performance. The quality of a drone's propeller directly affects its speed, stability, and power efficiency. As a company specializing in UAV paddle mold development and manufacturing, we provide customized solutions tailored to the unique needs of each client, ensuring that their drones achieve optimal performance.

Why Choose Customized Paddle Mold Development Services?

1. Standard Molds vs. Customized Molds

In the UAV industry, using standard molds may limit a drone's performance due to their generic nature. Standard molds often fail to meet the specific aerodynamic and structural demands of different drone types, leading to performance inefficiencies. In contrast, customized molds are designed to fit the exact requirements of each project, allowing for precise adjustments in propeller design, size, and material. These molds ensure that the drone operates at peak efficiency, offering significant advantages in speed, stability, and flight duration.

2. Meeting the Needs of Various Drone Types

Whether for industrial, commercial, or recreational drones, different applications require unique propeller designs. Drones used in agriculture, logistics, racing, or aerial photography have vastly different flight conditions and performance requirements. Our customized paddle mold services are adaptable, allowing us to create molds that are perfectly suited for the specific use case of each drone. This flexibility results in drones that are more efficient, durable, and capable of performing specialized tasks.

Our UAV Paddle Mold Development Process

Our process for creating custom UAV paddle molds is designed to provide precision, reliability, and customer satisfaction at every stage. From initial consultation to final delivery, we work closely with our clients to ensure that every detail is tailored to their specific requirements.

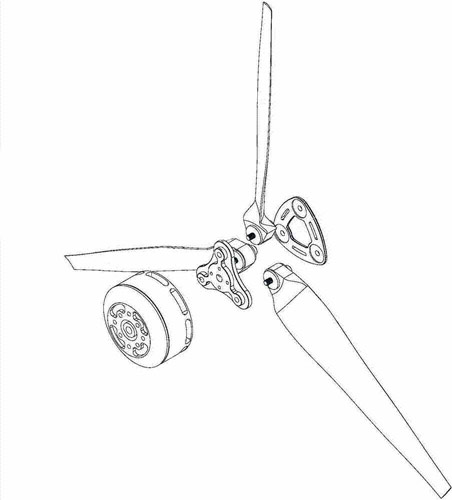

1. Needs Assessment and Custom Design

The first step in our process involves a thorough needs assessment. We gather all relevant information about the client's drone model, operational environment, and desired performance characteristics. This understanding allows us to design molds that optimize aerodynamic performance, reduce drag, and enhance power efficiency. Using advanced CAD/CAM software, our engineers create highly detailed mold designs that meet or exceed client expectations.

2. Material Selection and Technological Innovation

The choice of material is crucial to the success of a drone propeller. Depending on the application, we help our clients select the best materials for their molds, ensuring durability, strength, and performance. We offer a range of materials, including high-strength alloys, composite materials, and lightweight metals, each tailored to specific client needs. Learn more about how to choose inorganic materials for drone paddle molds and the advantages they offer in terms of strength and precision.

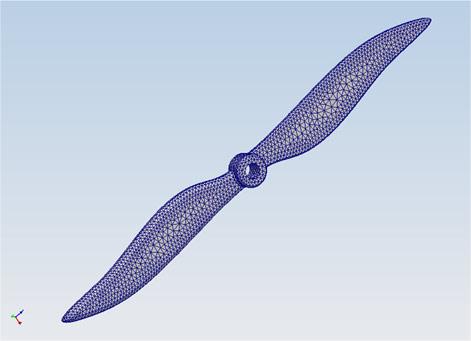

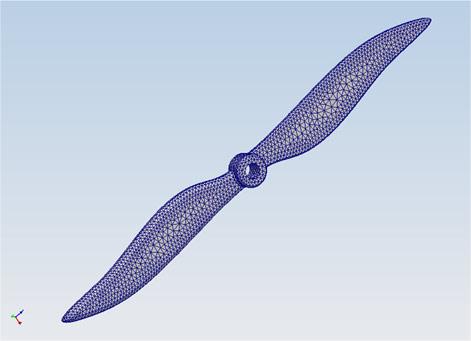

3. Precision Machining and Manufacturing

We use state-of-the-art CNC machines, laser cutting tools, and EDM (Electrical Discharge Machining) to guarantee precision in the manufacturing process. Our facility is equipped with the latest technology, allowing us to produce molds with tight tolerances and perfect surface finishes. Our focus on precision ensures that the propellers produced from our molds are consistent and meet the highest industry standards.

4. Mold Testing and Optimization

Before the molds are finalized, we perform rigorous testing to verify their performance. Through prototype testing and simulation, we ensure that the molds deliver the desired aerodynamic properties and structural integrity. Based on these tests, we offer refinements and adjustments to further optimize the design, guaranteeing the best possible results in the final product. For more information on common issues during the mold manufacturing process and how we address them, you can explore our detailed guide on common problems and solutions in UAV paddle mold manufacturing.

How Our Solutions Enhance Drone Performance

Our customized UAV paddle molds are designed to significantly improve the overall performance of drones. Here’s how our solutions can make a difference:

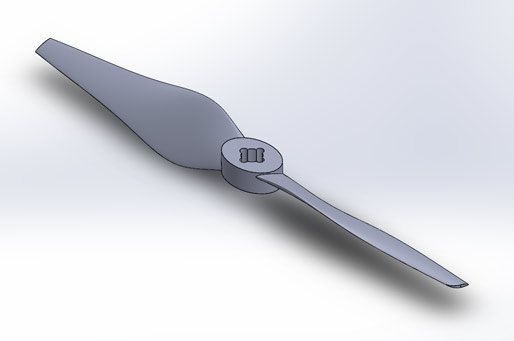

1. Optimized Aerodynamic Design

By tailoring the propeller’s shape and surface finish, we improve the aerodynamic performance of the drone. This results in increased speed, better maneuverability, and reduced energy consumption. Whether it’s for high-speed racing drones or commercial delivery drones, our designs maximize efficiency.

2. Increased Strength and Durability

The materials and designs we use ensure that the propellers are strong enough to withstand harsh flight conditions, including extreme temperatures, strong winds, and heavy loads. Our custom molds produce propellers that are durable, reducing the need for frequent replacements and lowering long-term operational costs.

3. Improved Production Efficiency and Cost-Effectiveness

Although custom molds may involve a higher initial investment, they provide substantial long-term savings. By optimizing the manufacturing process, our custom molds help reduce material waste, production time, and defects. This leads to a more efficient production cycle, allowing clients to scale up their operations while maintaining high-quality outputs.

Case Studies

1. Commercial Drone Propeller Optimization

We collaborated with a commercial drone manufacturer that required durable propellers capable of carrying heavy payloads for delivery purposes. By developing a custom mold tailored to their drone’s specifications, we increased the propeller's lift capacity and improved the overall flight efficiency. This solution enabled the client to expand their delivery services without compromising on reliability.

2. High-Performance Racing Drones

For a racing drone client, we designed a set of lightweight, high-performance propeller molds that reduced drag and improved top speeds. The custom design not only enhanced the drone's speed but also improved its stability during sharp turns, giving the client a competitive edge in racing events.

3. Agricultural Drones for Efficient Crop Monitoring

We worked with an agricultural drone company to design propellers that were quieter, more durable, and capable of flying long distances over large fields. The custom molds enabled the client to extend their drones' flight times, increase coverage area, and improve overall efficiency in crop monitoring tasks.

Why Choose Us?

Our company stands out for its expertise in UAV paddle mold development, backed by years of experience and a commitment to delivering high-quality, customized solutions.

1. Expertise and Flexibility

We specialize in providing custom solutions for diverse drone applications. Whether you need molds for commercial, industrial, or high-performance drones, we can design and manufacture molds that meet your exact requirements.

2. Cutting-Edge Technology and Innovation

Our use of advanced technology ensures that every mold we produce is of the highest quality. With precision machining, top-tier materials, and a focus on innovation, we ensure that our clients receive reliable molds that enhance their production capabilities.

3. Comprehensive Support and After-Sales Service

Our commitment to client satisfaction doesn’t end with mold delivery. We offer comprehensive after-sales support, including maintenance, repairs, and optimization services, ensuring that our molds remain efficient and functional over the long term.

Custom UAV paddle molds are essential for drones to achieve peak performance in today’s competitive markets. Our company offers tailored, high-precision mold development and manufacturing services that help clients enhance their drone operations, reduce costs, and stay ahead of the competition. Contact us today to learn more about how we can develop a customized mold solution to meet your specific needs.

Ready to take your drone performance to the next level? Contact us today to discuss how we can customize a propeller mold for your unique needs.

Ready to take your drone performance to the next level? Contact us today to discuss how we can customize a propeller mold for your unique needs.