Custom Plastic Injection Molds

We are a custom plastic mold factory that can accurately design and manufacture plastic molds to meet specific functional and performance requirements based on our customers' specific needs, thus producing plastic parts that fully meet the design specifications.

-

Injection Mold

- Our efficient injection molds significantly increase your production efficiency and shorten production cycles.

- Our precise mold manufacturing process guarantees high-quality products that meet your accuracy and consistency requirements.

- Optimized design and manufacturing processes help reduce waste and lower your production and maintenance costs.

Order now with a very high discount!

-

Injection Molding

- We handle a variety of materials and complex designs, offering a broad range of injection molding options.

- Our flexible production capacity allows us to quickly adapt to market changes and accelerate product launches.

- We offer competitive pricing and first-class production services to optimize your investment return.

Order now with a very high discount!

-

Bicolor Injection Mold

- Our bicolor injection molding technology enhances the aesthetic and functional appeal of products, making them more competitive in the market.

- Our technical team supports innovative designs, helping your products stand out in the market.

- Our integrated bicolor injection process reduces production steps, saving time and cost.

-

Overmolding

- Overmolding technology adds extra functionality and aesthetic to products, increasing their market value.

- Capable of handling various material combinations, we provide unique solutions for your products.

- Overmolding technology improves the structural strength and durability of products, extending their lifespan.

Order now with a very high discount!

-

Insert Molding

- Our insert molding technology can incorporate metal or other materials into plastic parts, enhancing product functionality.

- he integrated insert molding process improves production efficiency and product quality.

- Reducing or eliminating the need for post-assembly, lowering overall production costs.

Order now with a very high discount!

-

Rapid Prototyping

- Our rapid prototyping technology speeds up your product design and development process.

- Early prototype validation helps identify and resolve design issues, reducing development risk.

- Rapid prototyping supports innovative exploration, enabling you to test new ideas and concepts.

Order now with a very high discount!

-

Silicone Rubber Molded

- We offer custom silicone products tailored to your specific application needs.

- Our silicone products feature excellent temperature resistance, chemical resistance, and aging resistance.

- From medical to automotive, our silicone molding products are suitable for multiple industry requirements.

Order now with a very high discount!

-

Post Processing

- We offer a variety of post-processing services, including painting, silk-screening, and laser engraving, to enhance the visual appeal of your products.

- Our sophisticated surface treatment techniques enhance brand recognition and market appeal.

- Optimized processes ensure efficient and quality-controlled post-processing, shortening the overall production timeline.

Order now with a very high discount!

-

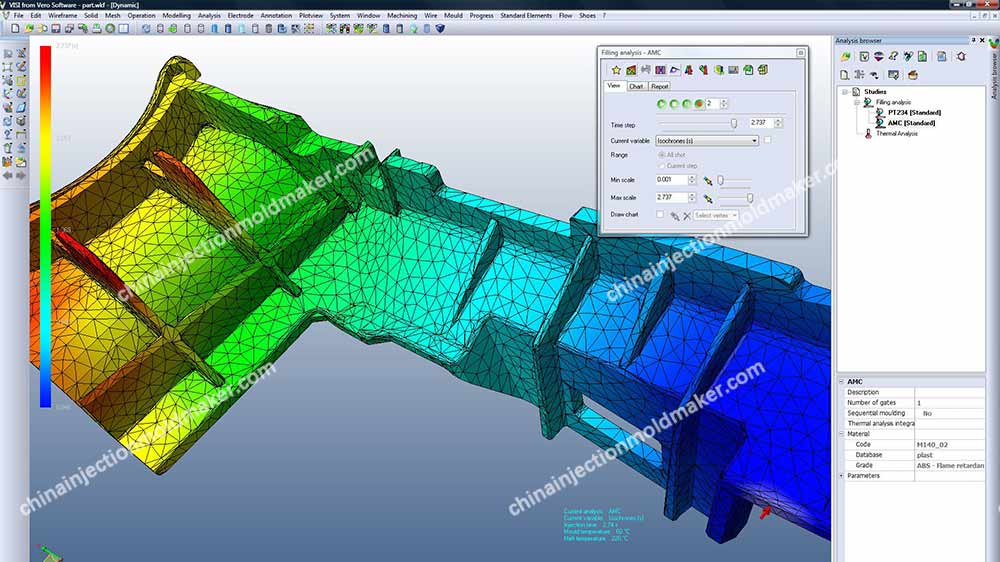

Cad Design

- Our experienced designers and engineers provide innovative and practical design solutions.

- Advanced CAD/CAM software is used for simulation and analysis, ensuring the feasibility and efficiency of designs.

- We encourage client participation in the design process to ensure the final product fully meets customer needs and expectations.

Order now with a very high discount!

Injection Moldings DFM

DsyStar recognizes the critical importance of DFM (Design for Manufacturability) in the pre-injection molding process. It helps to ensure that the design of parts or products is specifically optimized for plastic molds, identifying and resolving any potential manufacturing or efficiency issues before production begins.

Through DFM, we analyze the part design, material selection, mold design, and production parameter simulation during the product development phase. This reduces the number of reworks in design and production, accelerates the product development process, and enables a faster market launch of the products.