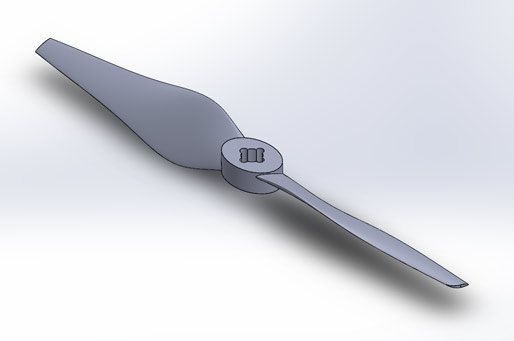

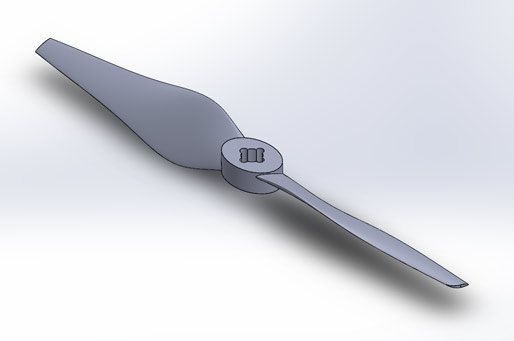

Common Problems and Solutions in UAV Paddle Mold Manufacturing

The performance of a drone is heavily influenced by the quality of its components, especially the propellers (paddles), which determine flight stability, speed, and efficiency. One of the most crucial steps in producing high-quality propellers is the mold manufacturing process. However, UAV paddle mold manufacturing can present several challenges that, if left unaddressed, can compromise the overall performance of the drone. In this article, we will outline the common problems in paddle mold manufacturing and provide effective solutions to ensure that your molds—and the propellers they create—meet the highest standards of precision and quality.

If you are looking for a fully tailored solution to your drone’s paddle mold needs, check out our Drone Paddle Mold Manufacturing Service-Customized Solutions, where we offer end-to-end services designed to meet specific client requirements.

1.Inaccurate Mold Design

Problem Description:

Inaccurate mold design is one of the most frequent challenges encountered in the manufacturing of UAV paddle molds. Even minor design flaws can lead to propellers that do not meet the required aerodynamic specifications, affecting flight stability and efficiency. This can result in increased drag or reduced control during operation, which negatively impacts the overall performance of the drone.

Solution:

The best way to solve this issue is through precise and thorough design using advanced CAD/CAM software. These tools allow for the creation of detailed, accurate 3D models of the mold, ensuring that every aspect is optimized for the drone's specific needs. Regular design validation through simulations of airflow and stress testing can further prevent performance issues.

In addition to design, choosing the right material for the mold is equally critical. Learn more about how to optimize mold performance by reading our article on Drone Paddle Mold Manufacturing Service-Customized Solutions, which highlights the importance of customized solutions in UAV mold manufacturing.

2.Improper Material Selection for Mold Manufacturing

Problem Description:

Selecting the wrong material for your UAV paddle mold can result in rapid wear, loss of precision, or even mold failure. The durability and performance of the mold largely depend on choosing materials that can withstand the demands of mass production while maintaining high precision.

Solution:

To ensure longevity and optimal performance, it is essential to use durable, high-quality materials for both the mold and the propellers. For instance, high-strength aluminum alloys or hardened steel are often recommended for mold production due to their ability to withstand heavy use without deforming. In addition to mold material, selecting the right material for the propeller is just as important.

For a deeper dive into choosing the most suitable materials for UAV paddle molds, be sure to check out our detailed guide on Inorganic Material Selection for Drone Paddle Molds. This article explores the benefits of using advanced materials in mold production and how they contribute to propeller efficiency and durability.

3.Poor Surface Finish on the Mold

Problem Description:

The surface finish of a mold is critical to the aerodynamic properties of the propellers it produces. A poor finish can result in uneven surfaces, causing the propellers to generate excessive turbulence during flight. This leads to performance inefficiencies such as increased noise, energy loss, and instability.

Solution:

Achieving a smooth surface finish requires precision machining techniques like CNC milling or EDM (Electrical Discharge Machining). Post-production polishing and surface treatment further ensure the mold's quality. These steps are necessary to guarantee that the propeller's surface is aerodynamically optimized and that any potential surface flaws are eliminated.

4.Mold Cooling and Temperature Control

Problem Description:

Inconsistent mold cooling or inadequate temperature control during the production process can cause internal stresses in the propellers, leading to issues such as warping, cracking, or structural weakness.

Solution:

To ensure uniform cooling, integrating a robust cooling system into the mold design is critical. Water channels or specialized cooling systems can help distribute temperature evenly across the mold during the production process. Additionally, installing temperature sensors in key areas of the mold allows for real-time monitoring and adjustments, maintaining the optimal temperature for each production run.

For more customized approaches to mold manufacturing, including cooling and temperature solutions, our Drone Paddle Mold Manufacturing Service-Customized Solutions offers tailored processes to meet specific client needs, ensuring high precision and consistency in every batch of propellers.

5.Mold Wear and Tear

Problem Description:

Mold wear is inevitable over time, but without proper maintenance, it can lead to defects in the finished propellers. Worn molds often produce parts with dimensional inaccuracies, which can degrade the drone's flight performance.

Solution:

Regular maintenance is essential for prolonging the life of the mold and ensuring it continues to produce high-quality propellers. This includes routine cleaning, application of protective coatings, and periodic inspections for any signs of wear or damage. By staying proactive with mold maintenance, you can reduce production downtime and avoid costly repairs or replacements.

For a more comprehensive overview of how we address wear and tear issues in mold production, explore our guide on Common Problems and Solutions in UAV Paddle Mold Manufacturing, which includes practical tips for maintaining mold quality and extending its lifespan.

6.Challenges in the Injection Molding of UAV Plastic Products

Problem Description:

In the production of UAV plastic components, including propellers, various challenges can arise during the injection molding process. Issues such as incomplete filling, warping, shrinkage, or surface defects can compromise the integrity and performance of the final product.

Solution:

To overcome these challenges, it’s crucial to ensure precise control over the injection molding parameters, including temperature, pressure, and material flow rate. Optimizing these variables can reduce defects and improve the quality of the molded UAV plastic products. Additionally, selecting the appropriate plastic materials for drone parts can significantly enhance their durability and functionality.

For more information on how to address these issues, visit our article on Challenges in the Injection Molding of UAV Plastic Products, where we discuss common problems and their solutions in detail.

7.Problems with UAV Paddle Overmolding and Material Coverage

Problem Description:

Many UAV paddle designs require the application of secondary materials, such as rubber or other composites, for enhanced performance characteristics like grip or noise reduction. However, the overmolding process can introduce complications such as poor adhesion, material separation, or inconsistencies in coverage.

Solution:

The success of the overmolding process depends on the compatibility of the base material and the secondary material. Proper surface preparation and the use of specialized adhesives or bonding agents can improve material adhesion. Additionally, careful control of the molding conditions, such as temperature and pressure, is essential to achieve uniform material coverage.

To learn more about the challenges involved in covering UAV paddles with secondary materials and how to solve them, check out our detailed article on UAV Paddle Overmolding and Material Coverage Issues.

Conclusion

Manufacturing UAV paddle molds involves overcoming several common challenges, from accurate design and material selection to cooling control and wear management. Addressing these issues with precision engineering and advanced materials ensures that your propellers not only meet performance expectations but also contribute to the overall efficiency and reliability of your drone.

Our team is dedicated to providing customized solutions for UAV paddle mold development. For more information about our approach, visit our Drone Paddle Mold Manufacturing Service-Customized Solutions page. Additionally, if you’re looking for high-quality drone molds, be sure to check out our UAV Mold Product Page to learn more about our products and services.